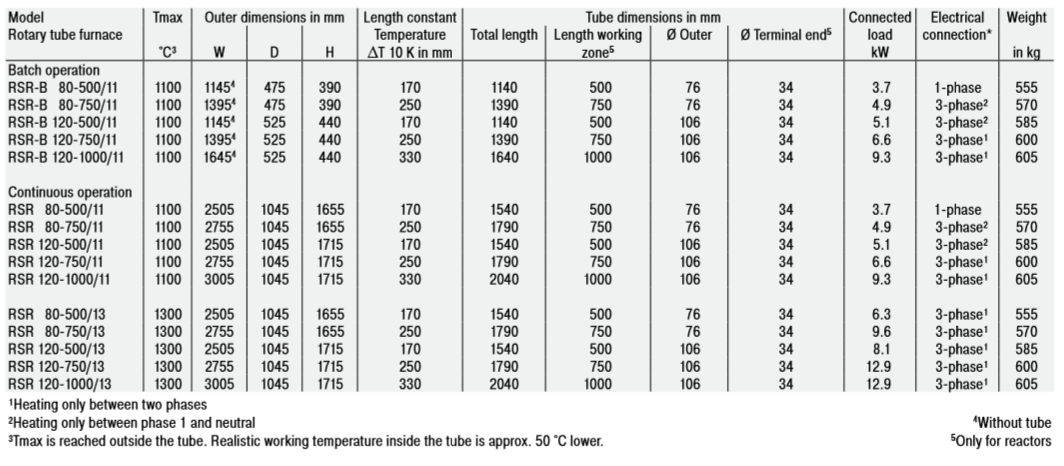

RSR 80-500/11 - RSR 120-1000/13, RSR-B 80-500/11 - RSR-B 120-1000/11

In general, these models can be used for continuous processing and/or batch operation.

If, for example, the focus lies on maintaining the individual grain characteristics of the material such as in drying or calcination, rotary tube furnaces of the RSR product line are the optimal solution. The permanently rotating working tube allows for the continuous movement of the charge.

In general, these models can be used for continuous processing and/or batch operation. While during a continuous process the charge is transported uniformly from one end to the other of the working tube, during batch operation, it can be heated-treated over a longer period in the furnace chamber thanks to the special shape of the quartz glass reactor (tapered tube ends).

The compact furnaces of the RSR-B product line are perfectly suited for batch operation. The versatile RSR furnaces can be equipped both with working tubes for continuous operation as well as with reactors for batch operation.

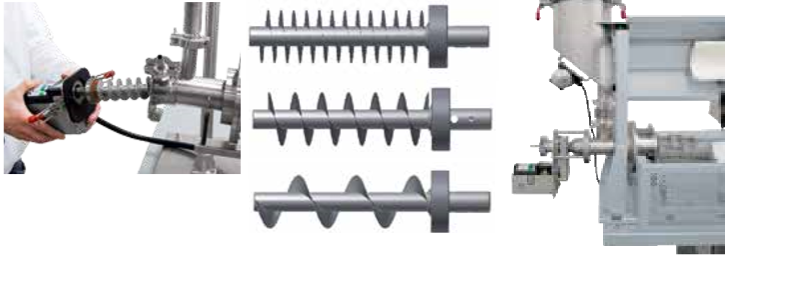

Depending on the process, charge and the required maximum temperature, various working tubes made of quartz glass, ceramic or metal can be used (see page 42). Depending on the application these models can be upgraded by adding suitable accessories such as filling funnels, electric feed screw for feeding material or gas supply systems for small production furnaces. Operation can take place in air, in non-flammable protective or reactive gases, or in a vacuum. The necessary equipment is available as additional equipment.